مولدات كومينز عالية الجودة بتردد 50 هرتز / 60 هرتز

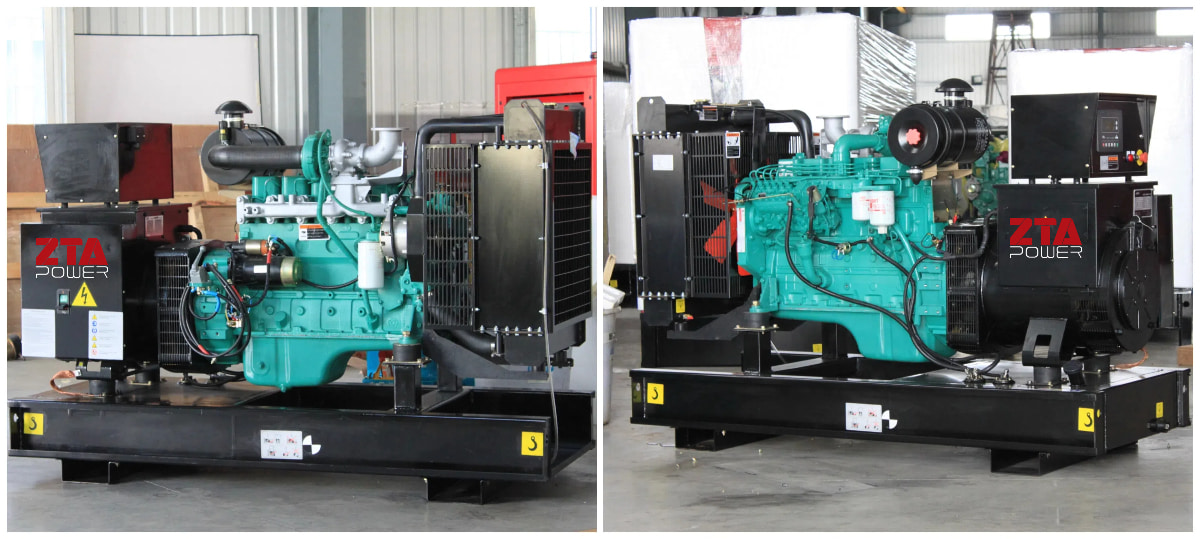

64kW/80kVA Cummins Prime Power Generator

4BTA3.9-G11 Engine

ماركة:

Dongfeng Cumminsالبند لا.:

ZC88أمر (موك):

1قسط:

T/T 30%, 70% Before shipmentأصل المنتج:

Chinaمنفذ الشحن:

Xiamen, Chinaمهلة:

3-4weeksوزن:

1300السلطة الرئيسية 64kw 80kVA Cummins 4BTA3.9-G11 Engine Powered Diesel Generator

Key Features:

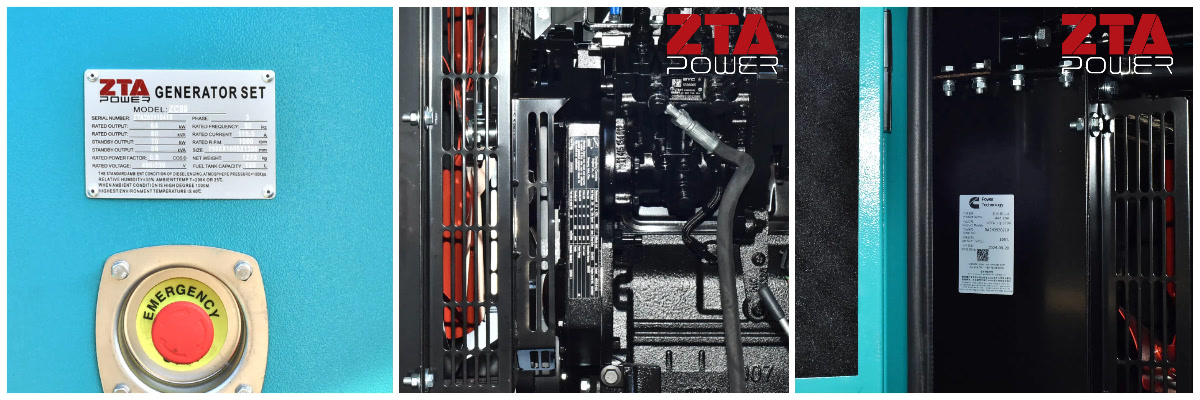

| Place of Origin | Fujian, China |

| Brand Name | ZTA Power |

| Model Number | ZC88 |

| Speed | 50HZ/1500RPM, 60HZ/1800RPM |

| Starting system | Auto Start, remote start, 24V DC Electric Start |

| Type | Open Type/Silent type/Mobile Type |

| Weight | Open: 850KG, Silent: 1350kg |

| Cooling System Type | Water-Cooled |

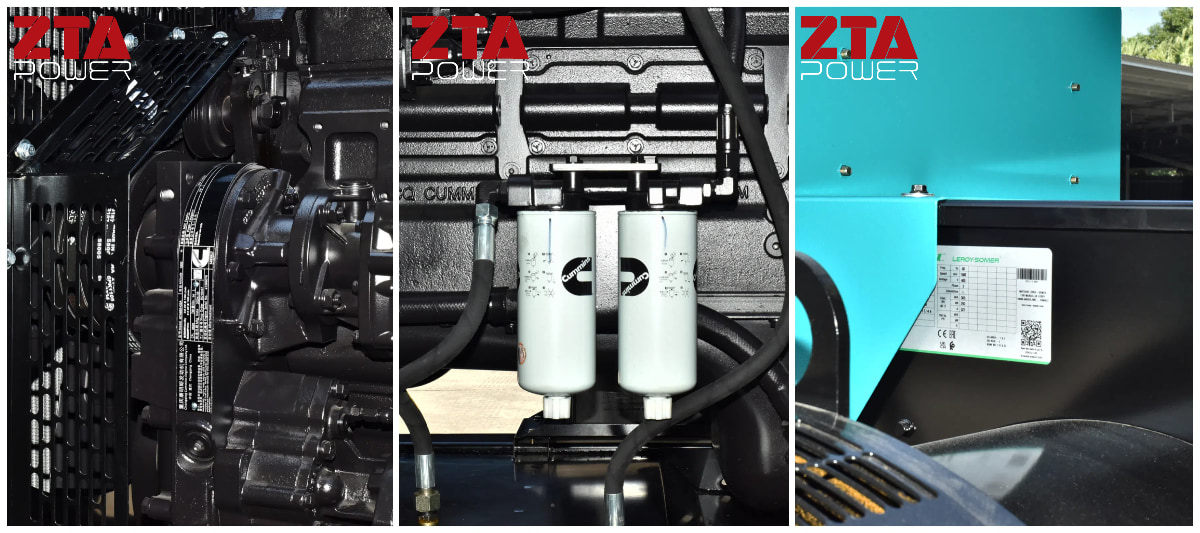

| Engine | Cummins 4BTA3.9-G11 |

| Alternator | Leroy somer TAL-A44-C(Stamford, Marathon,China Brand Alternator Also Supply) |

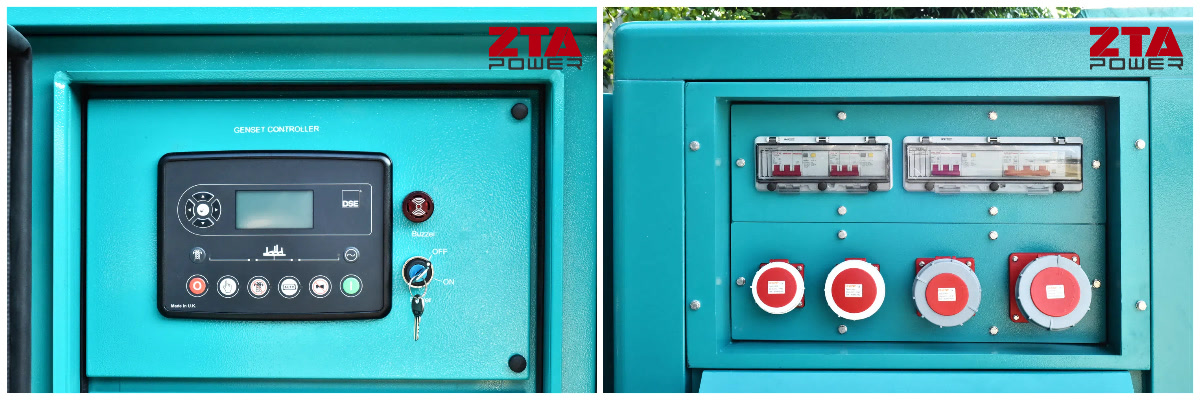

| Control Panel | UK Deepsea 6120(7320,Comap,Smartgen,Deif,DATAKOM Brand Also Available) |

| Base Frame | 8 hours Base Fuel Tank |

| Warranty | 1 year or 1000hours whichever comes first |

| Packing | Plastic Foam |

Cummins 4BTA3.9 Series Engine With Compact, lightweight, and cost-effective, the B-Series engine delivers cleaner, quieter, and more fuel-efficient performance. When maintained in strict accordance with service guidelines, it achieves an average trouble-free operation time of 1,500 hours and an average overhaul interval of 6,000 hours or longer.

Even under extreme duty cycle testing, this model demonstrates outstanding performance, with low noise levels, reduced weight, and high power-to-weight ratio—all thanks to its world-class reliability.

See more Detail check on the Video below:

Notice: Set picture quality to 1080p to view in high definition

Cummins 4BTA3.9-G11 Diesel Engine Specs

| Cummins Diesel Engine Model |

4BTA3.9-G11 |

|

Engine Output ( Prime Power) |

70kw |

|

Engine Output(Standby Power) |

80kw |

|

No. of Cylinder |

4-Cycle;In-line;4-Cylinde |

| Governor Type |

Electrical |

|

Aspiration |

Turbo Charged, After-Cooled |

| Bore×Stoke(mm) | 102×120 |

|

Displacement (L) |

3.9 |

| Fuel consumption at 100% full load (L/h) | 17.6 |

| Leroy somer Alternator Model | TAL-A44-C |

| Prime Power | 68kw/85kva |

| AVR Standard | R120(Shunt) |

| Voltage Available | 50HZ: 415/240V,400/230V, 380/220V, 220/127V, 60HZ, 480/277V, 220/127V |

| Insulation Class | H |

| Number of Wires |

6 |

| Pole | 4 |

| Protection | IP 23 |

| Voltage Regulation | ± 1% |

| Optional |

- Filters on air inlet: derating 5% - Filters on air inlet and air outlet (IP 44): derating 10% - Winding protections for harsh environments and relative humidity greater than 95% - Space heaters - Thermal protection for stator windings - Steel terminal box |

Advanced Control Systems

(UK Deepsea 6120,Smartgen 6120,Comap AMF 25,Deif Brand Etc.. Also Available Base on Customer Need)

Integrated automatic voltage regulator (AVR) and digital control panels (e.g., Deepsea, ComAp) for precise monitoring and control.

Features such as auto-start/stop, load sharing, and remote monitoring.

| Deepsea 6120 | Deepsea 7320 | |

| Over/under voltage protection | √ | √ |

| Over/under frequency protection | √ | √ |

| Phase rotation alarm | √ | √ |

| Overload /Low load protection | √ | √ |

| Overcurrent protection | √ | √ |

| Short circuit protection | √ | √ |

| Negative phase sequence protection | √ | √ |

| Earth fault protection | - | √ |

Circuit Breaker Specification:

| Manufacturer | Delixi/Chit/Schneider/ABB |

| Capacity | 160A |

| Pole | 3P |

Starting Battery Specification

| Battery Voltage | 12V |

| Battery Capacity | 36A |

| Battery type | Free maintenance, sealed lead-acid type |

| Battery Quantities | 2 Pcs |

Standard Supply Scope

| ① Auto Control Panel | ⓶Main Circuit Breaker |

| ⓷ Cooling Radiator | ⓸8 hours Base Fuel Tank |

| ⓹One Set 3 Filters(Diesel Filter, Air Filter, Lub Oil Filter) Install On Generator Set | ⓺Starting Motor |

| ⓻Exhaust Silencer | ⓼Starting Batter |

| ⓽Float Battery Charger | ⓾Flange |

Optional Supply Scope

| ① ATS | ⓶ Fuel and water separator |

|

③ Auto Fuel Pump |

④ External daily fuel tank |

|

⓹Elec.coolant Heater |

⑥ Oil drain Pump |

|

⓻Trailer & Silent Canopy |

⓼Synchronization System |

Silent Canopy Photo

Technical Support:

Impact of Water Contamination in Fuel on Diesel Generator Sets and Countermeasures

Abstract: Water mixing into fuel can affect combustion efficiency. As water has a lower boiling point than diesel, it may vaporize under high temperatures, potentially impairing diesel atomization and leading to incomplete combustion. This can result in carbon deposits, reduced engine power, and even white smoke emissions. Therefore, the impact of water in fuel on diesel generator sets is multifaceted, potentially causing insufficient power output, component damage, or even severe malfunctions. Attention should also be paid to potential sources of water in fuel, such as tank condensation, rainwater ingress, or contaminated fuel supply, to facilitate handling and preventive measures.

I. Main Impacts of Water in Fuel

1. Reduced Combustion Efficiency

Water mixed with diesel vaporizes during combustion, disrupting fuel atomization and causing incomplete combustion.

(1) Manifestations: Insufficient power, white smoke (water vapor), increased carbon deposits, higher fuel consumption.

(2) Long-term Consequences: Carbon buildup in the combustion chamber may damage piston rings or cylinder walls.

2. Corrosion of Fuel System

Water can cause corrosion of metal components (e.g., injectors, high-pressure fuel pumps, fuel tanks), especially when sulfur-containing diesel reacts with water to form sulfuric acid, accelerating corrosion.

Damage to Precision Components: Clogged or poorly atomizing fuel injectors, leading to uneven fuel injection or engine stalling.

3. Microbial Growth

The mixture of diesel and water provides an environment for microorganisms (bacteria, fungi) to grow, forming biofilms and acidic metabolites.

Consequences: Clogged fuel filters, corrosion of fuel tanks and lines, fuel turning dark and developing foul odor.

4. Lubrication Failure

Diesel fuel itself lubricates components like the high-pressure fuel pump. Water diluting the fuel reduces its lubricity, causing abnormal wear on parts.

Typical Failures: High-pressure fuel pump seizing, wear on plunger and barrel assemblies, potentially requiring complete replacement in severe cases.

5. Starting Difficulties and Operational Abnormalities

(1) Water freezing at low temperatures may block fuel lines, causing cold start failure.

(2) With excessive water content, the engine may experience intermittent stalling or fail to start.

6. Increased Emission Pollution

Incomplete combustion increases emissions of pollutants like CO and HC, potentially triggering alarms or clogging in emission control systems (e.g., DPF).

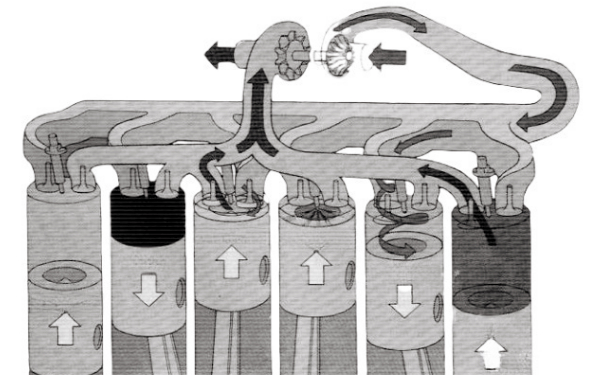

Schematic Diagram of Four-Stroke Diesel Engine Working Cycle

II. Countermeasures

1. Preventive Measures

(1) Fuel Quality Control: Ensure procurement of dry fuel; regularly check for water at the bottom of the fuel tank (using transparent sediment bowls).

(2) Tank Management: Maintain tank seals to prevent condensation (consider adding desiccants or periodically draining accumulated water).

(3) Install Water Separators/Filters: Install fuel-water separators; drain manually at regular intervals or opt for automatic draining models.

(4) Use Biocides: Apply specialized diesel biocides to address microbial contamination.

2. Fault Handling

(1) Drain and Flush: Immediately stop using contaminated fuel. Drain the fuel tank and lines, then flush the system with clean diesel.

(2) Replace Filters: Inspect and replace primary and secondary fuel filters to avoid residual contaminants.

(3) Component Inspection/Repair: Dismantle and inspect fuel injectors and high-pressure pumps; remove corrosion or replace worn parts.

(4) System Testing: After repairs, conduct a test run to observe fuel pressure, emissions, and vibration for normalcy.

3. Long-term Maintenance Recommendations

(1) Regular Maintenance Schedule: Inspect the fuel system and clean the tank every 500 operating hours or as specified in the manual.

(2) Environmental Adaptations: In humid regions, shorten filter replacement cycles and consider installing air dryers.

(3) Emergency Preparedness: Store backup fuel in sealed containers; equip with rapid water drainage tools and detection equipment.